INDUSTRIAL AUTOMATION IN PARAGUAY

With the digitization and the portfolio of Siemens automation products and solutions, we provide the opportunity to increase productivity and efficiency in all types of Industry.

"Technology and experience at the service of the Paraguayan industry!"

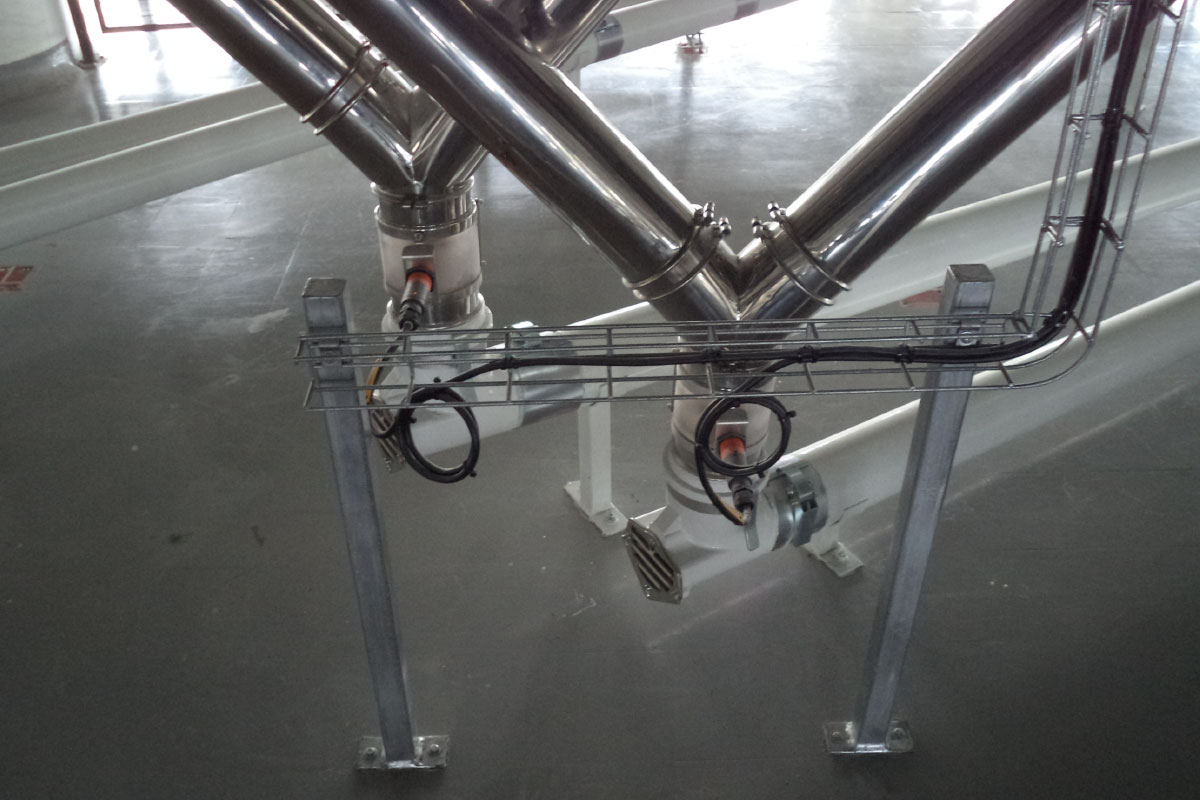

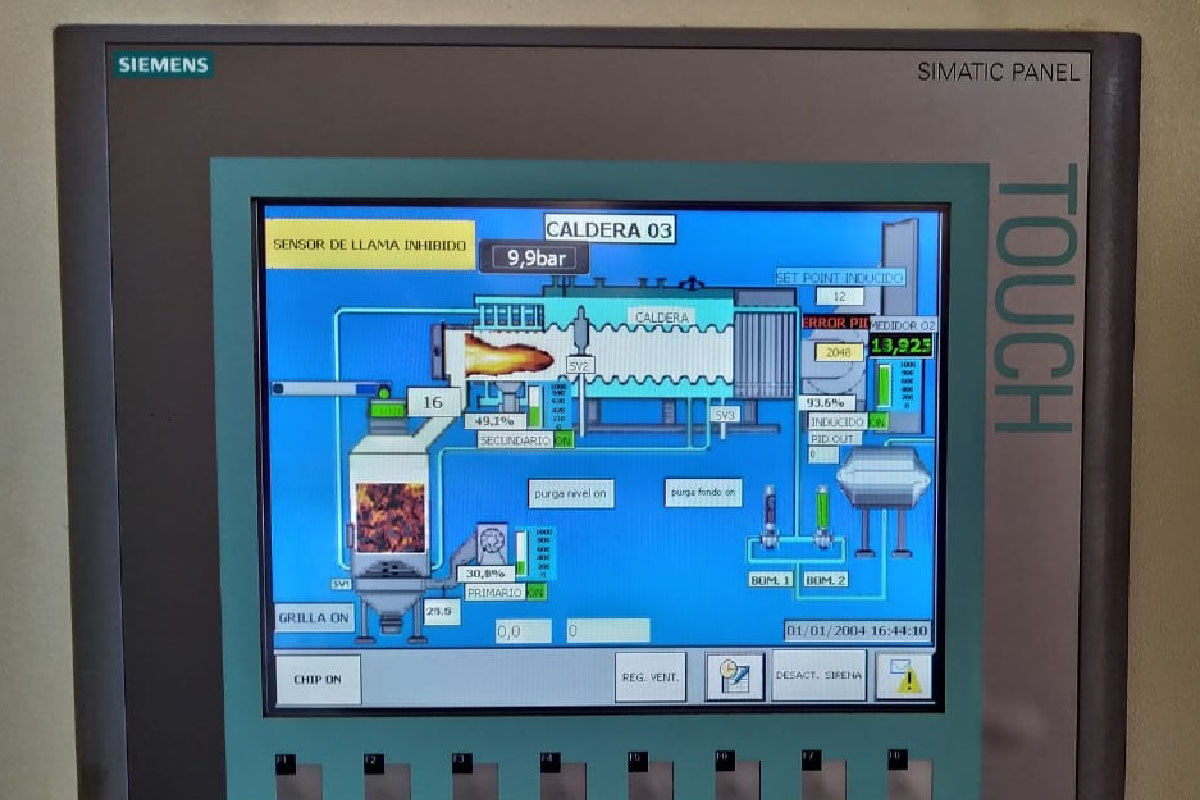

Our proposal for industrial solutions will improve the productivity, traceability and the safety of industrial processes. The lines of controllers and modules allow to connect and measure all the variables in a process, they are applicable to all types of industry and adaptable to simple and complex tasks.

With us you will find solutions for the agribusiness, the food and beverage industry (carbonated and non-carbonated), refrigerators, river ports, tobacco companies, lifting equipment, solutions for the textile industry, for the dairy industry, the sugar industry and any type application where flexibility and reliability are critical.

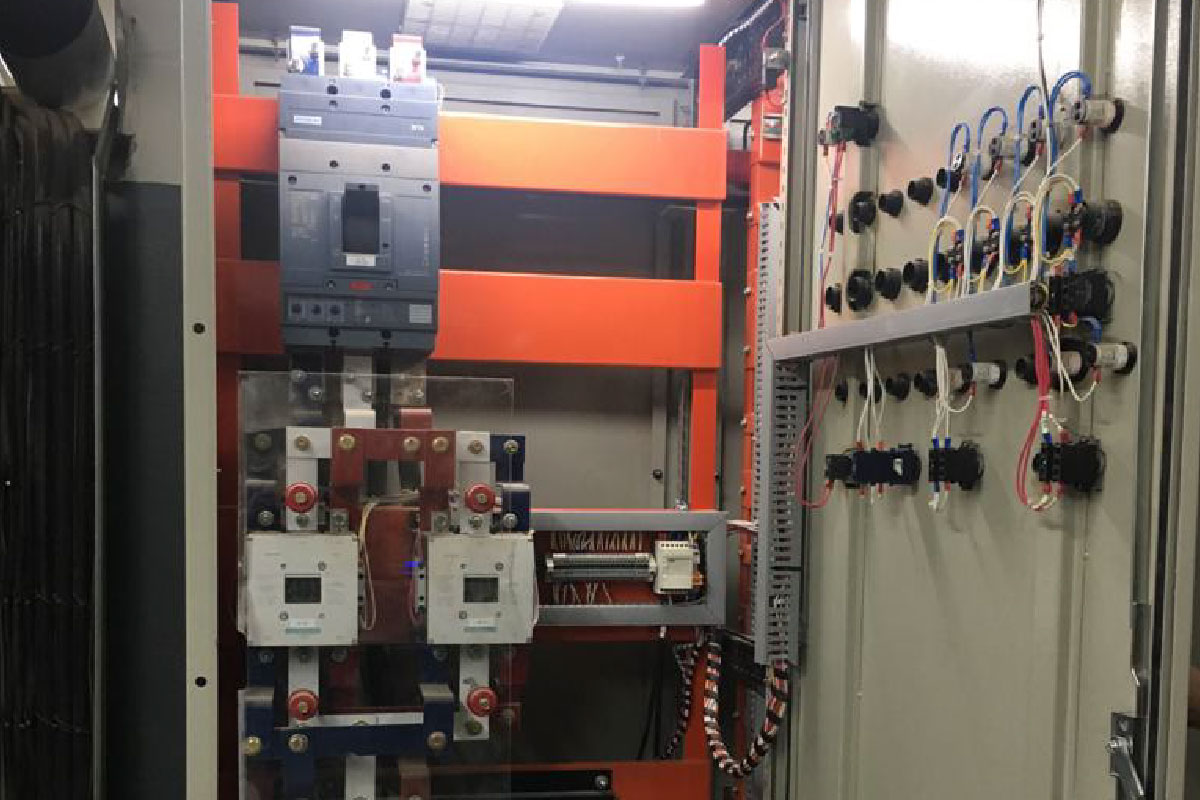

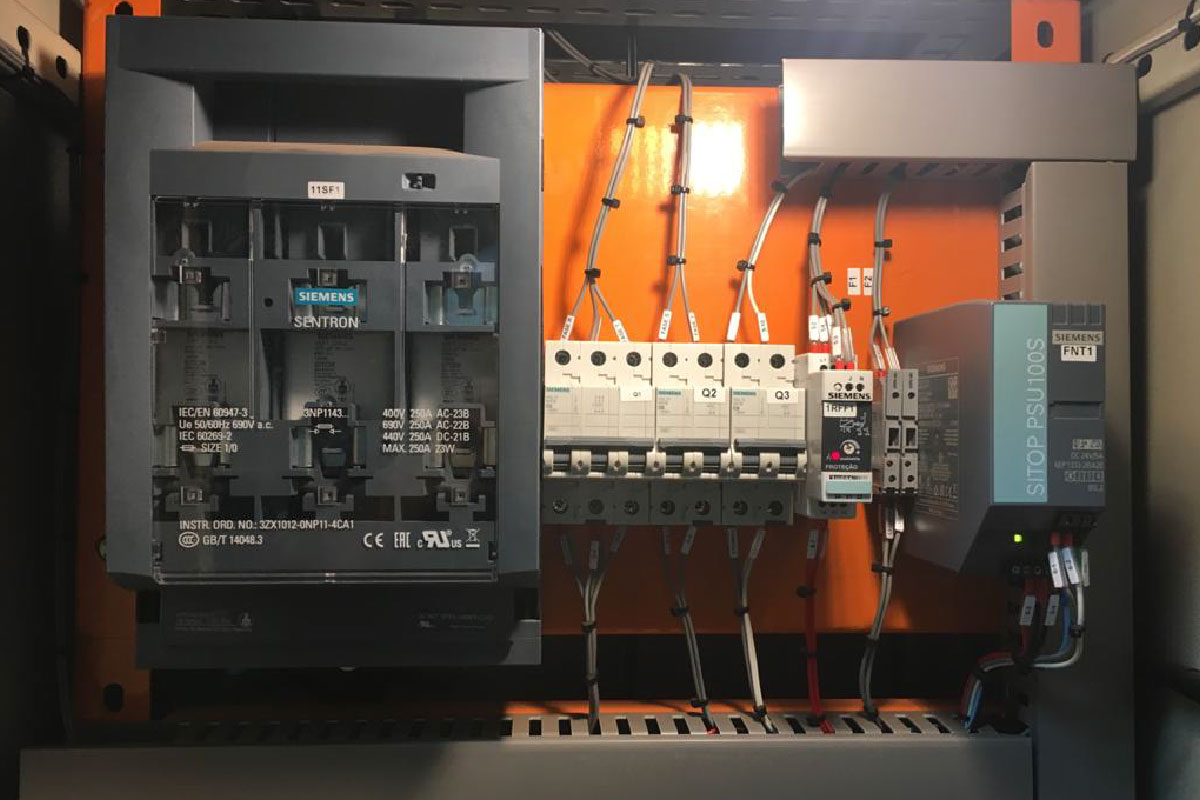

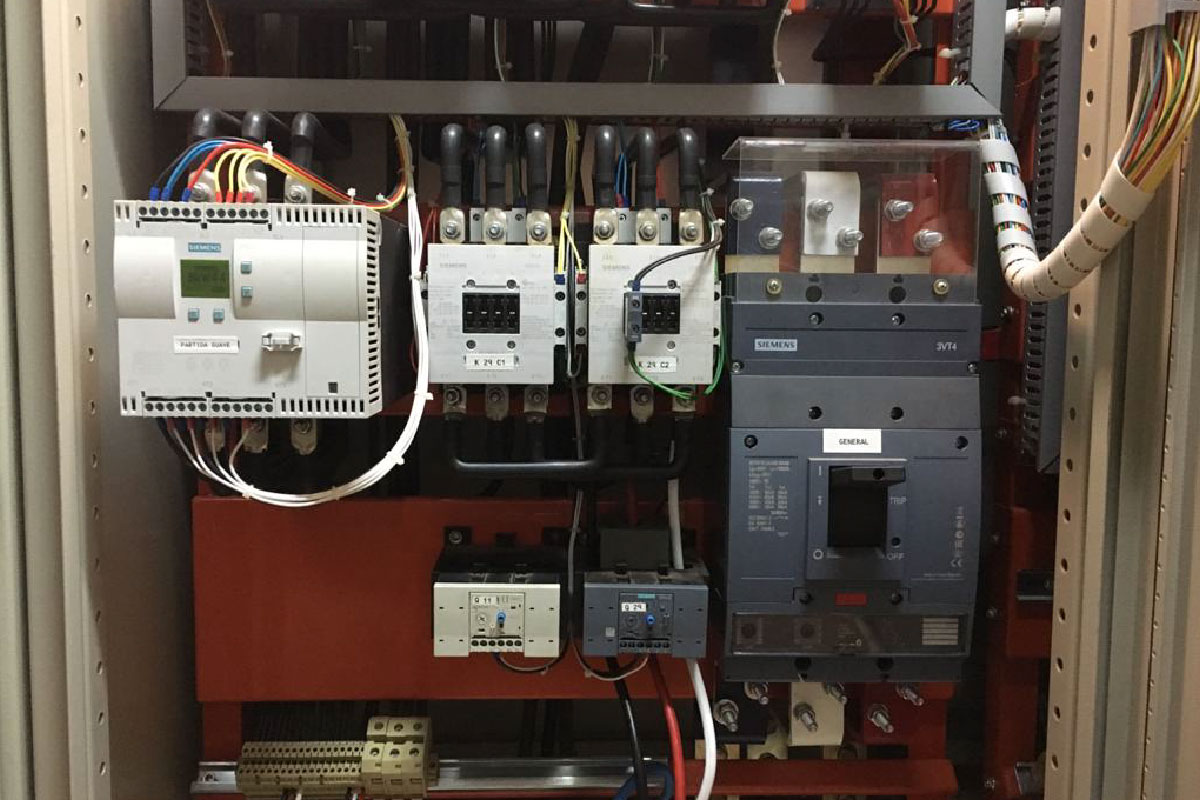

Our turnkey projects offer the integral solution for industrial investment, from planning to commissioning, with the Rieder - Siemens guarantee.

Our portfolio

LOGO! SYSTEMS FROM SIEMENS

The LOGO! from Siemens is the high-performance specialist for small automation tasks, either for capacitor banks, or for control of ventilation, for cooling, pumping, level, temperature, sequential operation of equipment and much more. It is small and robust, does not require a lot of space and its configuration is very simple thanks to a friendly software.

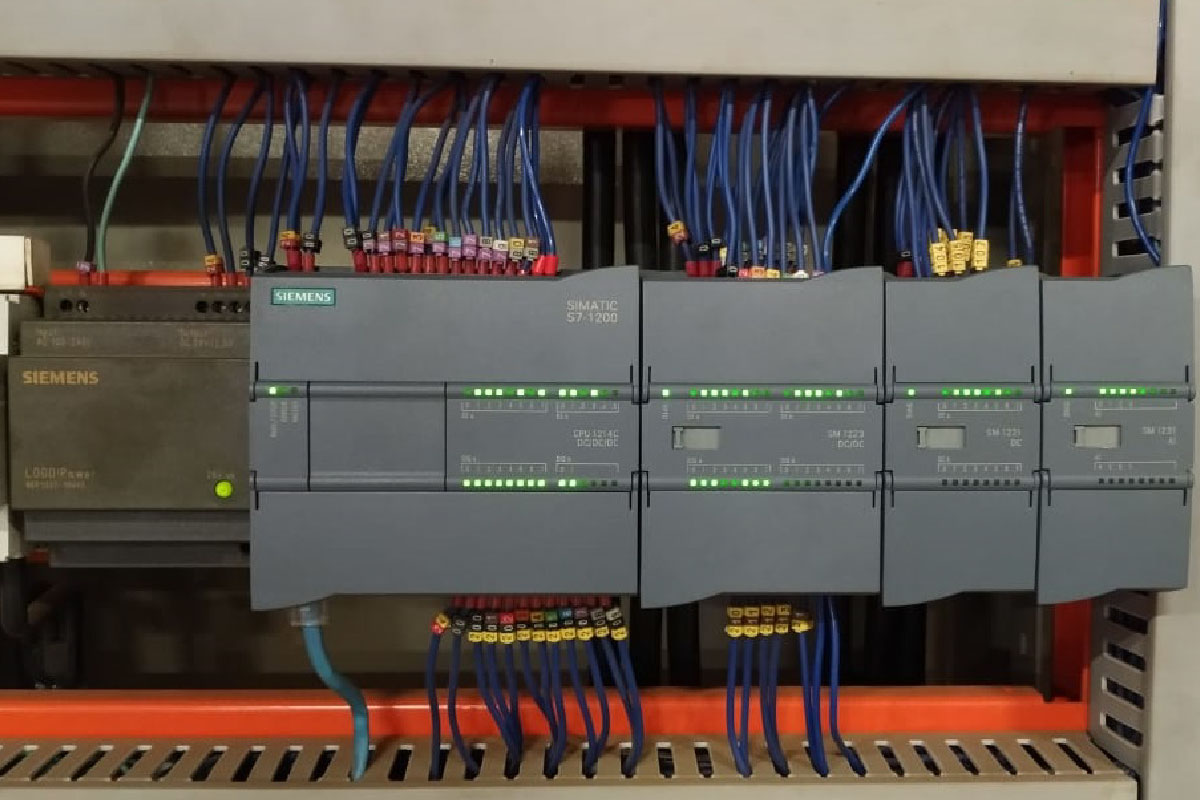

SIEMENS S7-1200 SYSTEM

The Siemens S7-1200 system is the smart solution for tasks involving automation in compact systems, communication technology, and special function options and versions for FAILSAFE solutions (SIL standard).

SIEMENS S7-1500 SYSTEM

These are the fastest controllers to meet the most demanding tasks. They have technology modules that ensure connectivity from the plant floor to the management stations for decision making.